Electromagnetic Shielding: Protecting Sensitive Equipment

Electromagnetic Shielding: Protecting Sensitive Equipment

Blog Article

In today's electrically noisy world, sensitive equipment is constantly bombarded by electromagnetic interference (EMI). This interference, generated by everything from power lines to wireless devices, can disrupt the operation of sensitive electronics, leading to errors, malfunctions, and even permanent damage. Electromagnetic shielding provides a crucial defense against EMI, safeguarding sensitive equipment and ensuring its reliable performance.

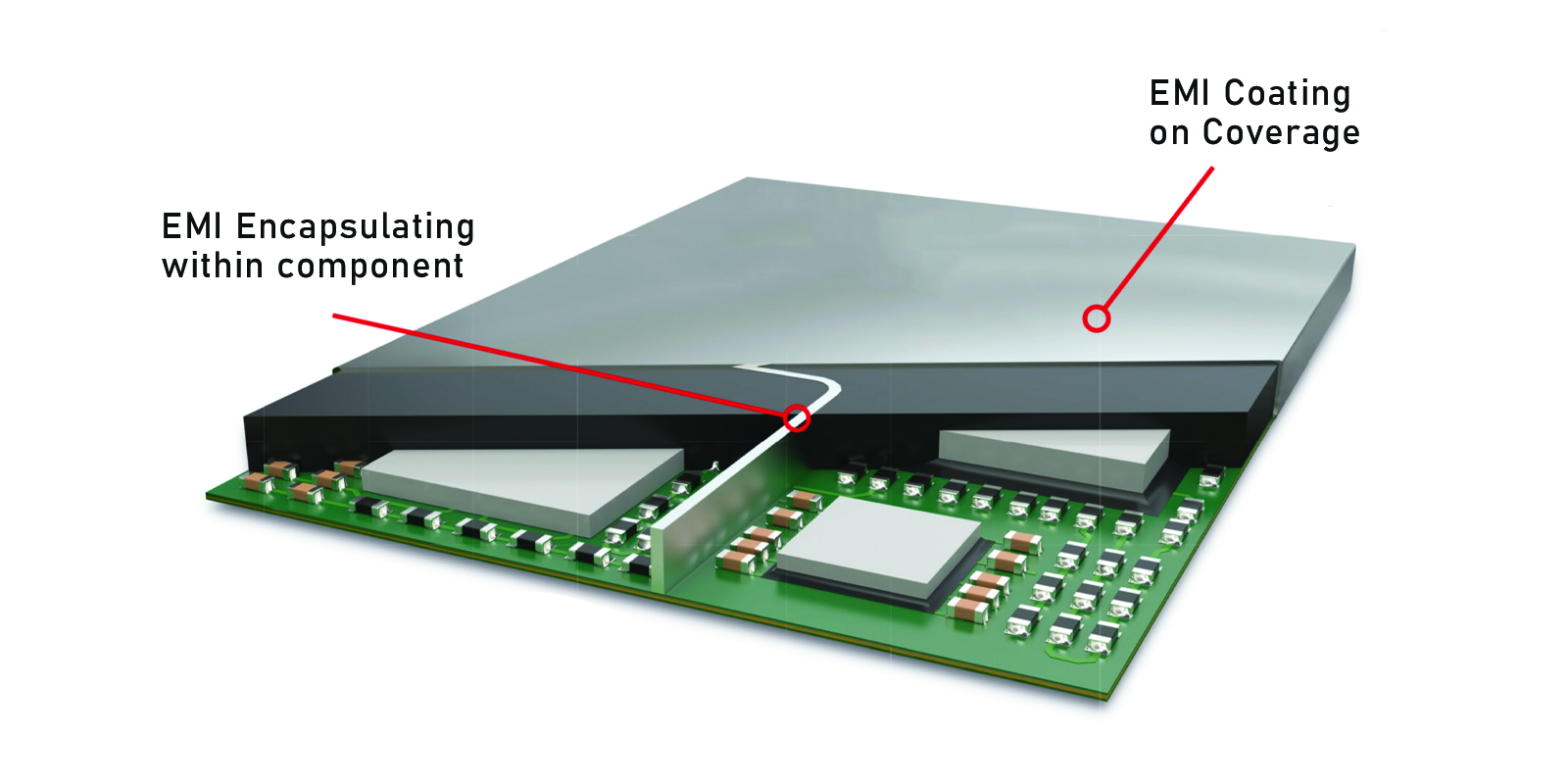

Electromagnetic shielding, also known as RF shielding or Faraday cage shielding, involves enclosing sensitive equipment within a conductive barrier that blocks the passage of electromagnetic radiation. This barrier, typically constructed from conductive materials like copper, aluminum, or steel, works on the principle of Faraday's law of induction. When electromagnetic waves encounter the conductive shield, they induce currents within the material. These currents, in turn, generate their own electromagnetic fields that oppose and effectively cancel out the incoming radiation, preventing it from reaching the equipment inside.

The effectiveness of electromagnetic shielding is measured in decibels (dB), representing the reduction in electromagnetic field strength achieved by the shield. A higher dB value indicates better shielding performance. The required shielding effectiveness depends on the sensitivity of the equipment being protected and the level of ambient EMI.

Several factors influence the effectiveness of electromagnetic shielding:

Material Conductivity: Highly conductive materials, such as copper, offer superior shielding performance. Aluminum is a good compromise between cost and conductivity, while steel is often used for lower frequency shielding.

Shield Thickness: Thicker materials generally provide better shielding, especially at lower frequencies.

Joints and Seams: Any gaps or discontinuities in the shield can compromise its effectiveness. Joints and seams must be carefully designed and constructed to ensure continuous conductivity. Welding or soldering provides the best seal, but conductive gaskets or tapes can be used for less demanding applications.

Apertures and Penetrations: Openings for cables, connectors, or ventilation can significantly reduce shielding effectiveness. These openings must be carefully designed and shielded to minimize RF leakage. Shielded connectors, feedthrough filters, and waveguides are often used to maintain shielding integrity.

Frequency of the Interference: Shielding effectiveness can vary depending on the frequency of the electromagnetic radiation. Lower frequencies are generally more challenging to shield than higher frequencies.

Electromagnetic shielding finds applications in a wide range of industries and applications:

Electronics Manufacturing: Shielded enclosures are used for testing and characterizing electronic components and devices, ensuring accurate measurements without interference from the surrounding environment.

Telecommunications: Shielding protects sensitive communication equipment from EMI, ensuring reliable signal transmission and reception.

Medical Imaging: MRI machines and other medical imaging devices rely on shielded rooms to prevent external RF noise from interfering with the imaging process.

Aerospace and Defense: Shielding is crucial for protecting sensitive electronic systems in aircraft, spacecraft, and military vehicles from EMI.

Automotive: Modern vehicles contain numerous electronic systems that can be susceptible to EMI. Shielding is used to protect these systems and ensure their reliable operation.

Data Centers: RF Shielding protects sensitive data center equipment from EMI, preventing data corruption and system failures.

Research Laboratories: Shielded rooms are used for conducting experiments that require a controlled electromagnetic environment.

Choosing the right shielding solution depends on the specific requirements of the application. Factors to consider include the frequency range of the interference, the required shielding effectiveness, the size and configuration of the equipment being protected, and the environmental conditions. For highly demanding applications, custom-designed shielding solutions may be necessary.

Implementing effective electromagnetic shielding is crucial for protecting sensitive equipment from the harmful effects of EMI. By carefully considering the factors outlined above, engineers and technicians can design and implement shielding solutions that ensure the reliable operation of electronic systems in today's increasingly complex electromagnetic environment. As technology continues to advance and the use of electronic devices proliferates, the importance of electromagnetic shielding will only continue to grow.