Choosing the Right Shielded Box for Your Needs

Choosing the Right Shielded Box for Your Needs

Blog Article

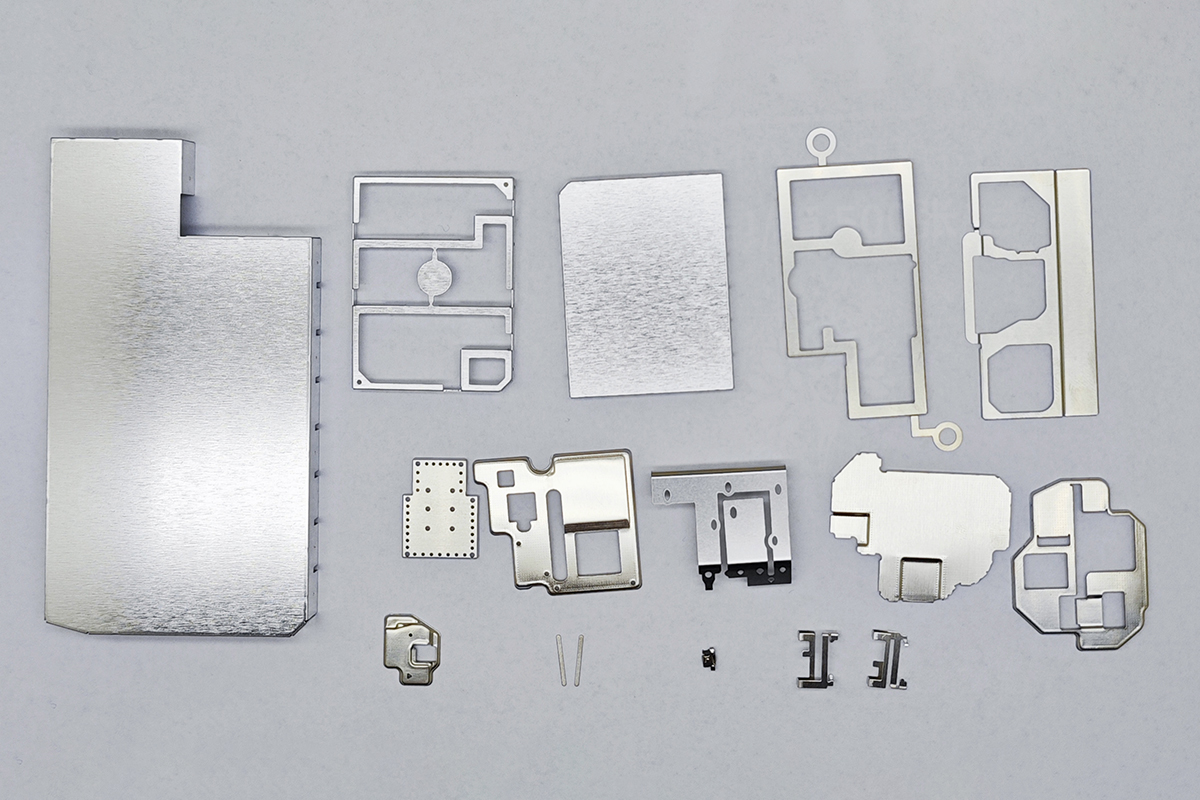

Shielded boxes, also known as RF enclosures or Faraday cages, are essential tools for controlling and managing radio frequency (RF) energy. They provide a controlled environment for testing, protecting sensitive equipment, and ensuring electromagnetic compatibility (EMC). Selecting the right shielded box is crucial for achieving the desired level of shielding effectiveness and meeting specific application requirements. This article outlines the key factors to consider when choosing a shielded box.

1. Frequency Range: The most critical factor is the frequency range of the signals you need to shield. Different materials and construction techniques offer varying levels of shielding effectiveness across different frequencies. Lower frequencies are generally more challenging to shield than higher frequencies. Specify the lowest and highest frequencies of interest to ensure the box provides adequate attenuation.

2. Shielding Effectiveness: Shielding effectiveness, measured in decibels (dB), indicates the reduction in electromagnetic field strength achieved by the enclosure. A higher dB value signifies better shielding performance. Determine the required shielding effectiveness based on the sensitivity of the equipment being shielded and the level of ambient RF noise. Consider a safety margin to account for potential future needs.

3. Material: The choice of material significantly impacts shielding effectiveness and cost.

Copper: Offers excellent conductivity and shielding performance but is more expensive. Often preferred for high-frequency applications and demanding shielding requirements.

Aluminum: A good compromise between cost and performance. Provides good shielding effectiveness for a wide range of frequencies and is lighter than copper or steel.

Steel: Robust and cost-effective, particularly for lower frequency shielding. Heavier than aluminum or copper.

Conductive Coatings: For less demanding applications, enclosures made from non-conductive materials can be coated with conductive paints or sprays.

4. Size and Configuration: Consider the internal dimensions required to accommodate the equipment or devices being shielded. Ensure adequate space for cables, connectors, and any necessary test equipment. Also, consider the external dimensions and whether the box needs to fit within a specific space. Think about the configuration of the box – do you need a tabletop model, a rack-mounted enclosure, or a larger chamber?

5. Access and Ports: Plan for any necessary access panels, doors, or ports for cables, connectors, or antennas. These openings can compromise shielding effectiveness if not designed carefully. Ensure that all openings are properly sealed with conductive gaskets or other shielding mechanisms. Consider using shielded connectors and feedthrough filters for cables passing through the enclosure walls.

6. Door and Latching Mechanism: If a door is required, it should be designed with overlapping conductive surfaces and a secure latching mechanism to maintain shielding integrity. The door should be easy to open and close while ensuring a tight seal. Consider the frequency of access required and choose a latching mechanism that is both secure and convenient.

7. Ventilation and Cooling: If the shielded box will house equipment that generates heat, consider incorporating ventilation or cooling mechanisms. Ensure that any vents or openings are properly shielded to prevent RF leakage. Consider using shielded fans or heat exchangers to maintain the shielding effectiveness.

8. Grounding: Proper grounding is essential for effective shielding. Ensure the shielded box is connected to a good earth ground using a short, low-impedance connection. This helps to dissipate any induced currents and improve shielding performance.

9. Customization: For specific requirements, consider a custom-designed shielded box. Manufacturers can tailor the size, material, shielding effectiveness, and other features to meet your exact needs. This is often necessary for highly specialized applications or when dealing with unique challenges.

10. Cost: The cost of a shielded box can vary significantly depending on the material, size, shielding effectiveness, and other features. Balance your budget with your performance requirements. Consider the long-term cost of ownership, including maintenance and potential upgrades.

11. Manufacturer Reputation and Support: Choose a reputable manufacturer with experience in designing and building shielded boxes. Look for a manufacturer that offers good technical support and can assist you in selecting the right product for your needs.

By carefully considering these factors, you can choose the right shielded box to meet your specific requirements and ensure the integrity of your electronic testing and operations. Remember that investing in a high-quality shielded box is a worthwhile investment that can save you time, money, and frustration in the long run.